The QLBY series mobile asphalt mixer adopts a modular structure, which is simple, aesthetically pleasing, environmentally friendly, energy-saving, reliable in quality, easy to operate, and quick to install and transfer; The produced asphalt concrete finished materials have good quality and stable performance, and are widely used in the construction of highways, bridges, municipal and other infrastructure, as well as daily maintenance and repair of black road surfaces.

Main structural features:

1. Design the entire combination structure of the drying drum and mixing tank on a mobile trailer for easy overall movement;

2. The mixer adopts a unique double horizontal shaft structure, which forms a strong boiling effect during the mixing process, thereby ensuring that various aggregates are fully mixed.

3. Hot aggregate lifting is a lifting equipment that uses densely arranged hanging buckets for vertical transportation, which is simple, convenient, stable, and reliable.

4. Aggregates, asphalt, and mineral powder are measured using electronic weighing sensors.

5. The powder is lifted with a spiral seal, preventing the loss of stone powder and ensuring safety and environmental protection.

6. Adopting cyclone jet combustion technology, high-pressure fuel injection atomization is good, coupled with a cyclone furnace as the combustion chamber, complete combustion, automatic ignition, and easy to use; The furnace head is separated from the furnace chamber, and the furnace chamber can be pushed and pulled, making it more convenient to replace burnt furnace head bricks. It has the characteristics of large heat capacity, high heat intensity, and good economic benefits.

Automatic metering and batching station

The automatic metering and batching station adopts a three bucket cumulative metering method, using a loader for matching aggregate supply operations. Electronic cumulative metering is carried out through a PLC programmable controller, with automatic compensation for differences, high metering accuracy, and small errors. The belt conveyor is equipped with a belt scraper and a deviation adjustment wheel.

Note: Our company can also design the batching station as a movable structure according to customer needs.

Drying drum

1. The cylinder is made of high-strength alloy structural steel Q345 (16Mn), which has the ability to resist erosion and high-temperature deformation.

2. With a special blade arrangement, the material forms a strong axial movement inside the cylinder, ensuring uniform heating of the material and greatly improving the quality of the finished product.

3. The cylinder has a thrust device to prevent axial movement of the drying drum during rotation, thereby avoiding wear on the end of the supporting roller and the collision and wear of the sealing rings at both ends of the cylinder.

4. The main moving parts are connected with labyrinth seals to prevent dust from overflowing and achieve good sealing effect.

Mixing tank

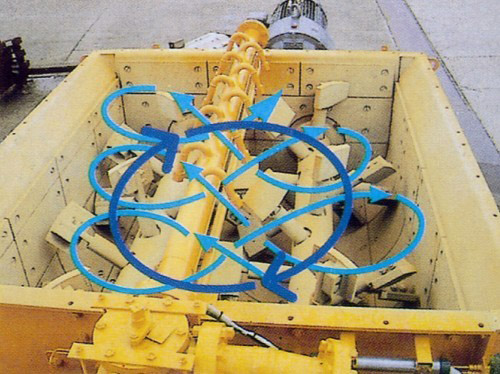

The mixer is a double horizontal shaft forced mixer, which overcomes the problem of poor quality of finished materials caused by mixing dead corners in single horizontal shaft mixers. This mixer is produced using advanced manufacturing equipment and processing technology in China, with a special double horizontal shaft structure that creates a strong boiling effect during the mixing process, allowing various materials to be evenly, quickly, and thoroughly mixed. The lining plate, mixing arm, and blades are all made of wear-resistant, high-strength high chromium alloy steel, with a long service life.

Burner

Adopting internationally renowned burners with high technological content, high flame temperature, sufficient combustion, low fuel consumption, and significant economic benefits. Suitable for various fuels, such as heavy oil, diesel, natural gas, liquefied gas, coal, etc.

Finished product warehouse

The finished product warehouse is lifted by a steel wire rope winch, which comes with a brake device and a large cylinder diameter cylinder opening the door for unloading. The capacities are 2.5 tons, 5 tons, and 9 tons respectively. The lifting bucket adopts dual stroke limit and PLC time control three-level protection, which ensures stable operation, safety and reliability.

Control room

The control room is exquisite and beautiful, providing users with a comfortable and spacious operating environment, greatly reducing adverse factors such as dust and noise. The control room is in a detachable form, equipped with split air conditioning, aluminum alloy sliding windows, and wooden floor decoration, creating a spiritual space. Operators can achieve automated centralized control of equipment operation in the control room, making it easy to operate.

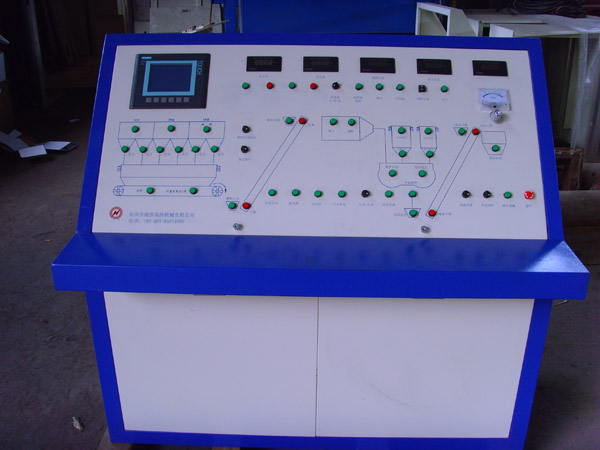

Operation cabinet

1. A brand new independently developed configuration software that achieves a user-friendly interface and human-machine dialogue function,

2. Touch screen display, PLC programmable controller centralized control, capable of fully automatic, semi-automatic, and manual operation. Simple and convenient operation, intuitive interface.

3. Unique weighing function, stone weighing adopts cumulative measurement, fast replenishment, and automatic compensation for differences.

4. Powerful query function, record and print main production data.

5. Multi directional practical process flow, convenient management of formulas and production parameters.

6. Powerful and accurate fault monitoring and alarm functions.

Coal fired (oil fired) direct heating asphalt tank

This equipment is a coal-fired (oil fired) direct heating asphalt storage and heating tank designed for road construction and maintenance units. The equipment has functions such as asphalt storage, preheating, dehydration, heating, temperature indication, and high temperature alarm. It is movable as a whole, easy to lift, maintain, and transport, and does not require the construction of a foundation for installation. It can be ignited and produced on a simple and flat site. During the heating process, the asphalt process is automatically operated under negative pressure, and the pump and pipeline are preheated by themselves. The intermediate program does not require direct manual operation. During equipment operation, only water and coal need to be added, ash and slag should be removed, and high-temperature asphalt should be pumped out.

YK-20/30/50 asphalt heating tanks have storage capacities of 20m ³, 30m ³, and 50m ³, respectively. The output of finished asphalt from a single heater is 4-5T/hour.