In order to meet the needs of high-grade highway construction, Nanqiao Company has developed LB1000 to 5000 asphalt concrete mixing equipment. The complete set of equipment consists of a cold silo system, a drying system, a main mixing building, an aggregate lifting system, a screening and metering system, a thermal oil heating asphalt supply system, a pulse bag dust removal system, and a finished material storage system. The entire equipment is equipped with a microcomputer automatic control system. The main building is made of high-quality steel plates folded and formed, using imported burners, Toledo sensors, Siemens electrical components, and Advantech industrial control computers. The whole machine has a reasonable structure, high degree of automation, and is safe and reliable.

1. Modular cold storage bin system

① The modular design of the cold aggregate bin and belt conveyor can be combined according to user needs;

② The output of the belt is controlled by stepless frequency conversion speed regulation technology, which can automatically adjust the speed according to the output setting and ratio requirements;

③ Each warehouse is equipped with a coarse waste isolation net and an empty bucket alarm device at the feeding port to alert in case of material shortage or blockage;

④ The aggregate belt and feeding belt are made of high toughness rubber belt, with anti slip auxiliary drum and cleaning scraper

2. Drying and heating drum

① The drying drum is made of 16Mn wear-resistant and high-temperature resistant steel plate, which is automatically welded by a fully automatic submerged arc welding machine and has a long service life. External addition of silicate fiber and stainless steel exterior, sturdy and beautiful;

② Driven by the friction of the rollers of four axle mounted reduction motors, the roller surface has been strengthened and treated;

③ The cylinder is insulated with rock wool and covered with stainless steel surface decoration to effectively prevent heat loss;

④ The discharge port uses an infrared thermometer to detect the heating temperature of the aggregate.

3. Efficient dust removal system

① The upper part of the bag filter is a fiber filter bag supported by a steel cage skeleton. Introducing internationally renowned brands for efficient and durable filter bags;

② Using an atmospheric blowback system to reverse the external airflow through the bag, causing dust to fall off;

③ The lower part of the dust collector collects fine dust, which is discharged by a screw conveyor or sent to a powder elevator.

4. Screening system

① The aggregate hoist is driven by a high wear-resistant plate chain, which is not easily worn and stretched, has a low operating speed, smooth transmission, and long service life.

② This system adopts a dual axis self synchronous linear vibrating screen with 4-6 layers of mesh. Externally sealed to prevent dust, insulated with rock wool, and covered with colored steel plates on the outermost layer.

5. Asphalt heating supply system

① Using thermal oil heating method, the heating is rapid and uniform;

② The asphalt tank and gas pipeline are insulated with rock wool, effectively preventing heat loss.

6. Mixing system

① Adopting a synchronous drive double horizontal shaft mixer for forced mixing, ensuring smooth and efficient operation;

② Carefully designed mixing blades can achieve uniform and rapid mixing, with a service life of no less than 100000 batches;

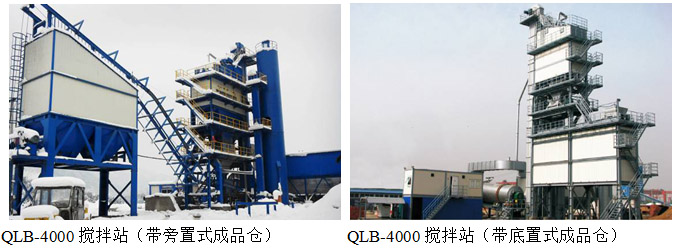

7. Finished material storage system (this system can be divided into two types: side mounted and bottom mounted)

7.1 Side mounted finished product warehouse

① The overall structure adopts modular design, compact structure, and safe and reliable use;

② There is a special structure inside the silo to prevent the segregation of finished materials. The exterior of the silo is insulated with rock wool and covered with colored steel plates;

③ The material transport trolley is pulled by a winch, running smoothly and with precise positioning.

7.2 Bottom mounted finished product warehouse

① The use of bottom mounted finished product silos greatly saves equipment footprint and reduces equipment failure rates;

② It can reduce the overflow of blue smoke or dust during the discharge process.

③ The warehouse adopts rock wool insulation to reduce the temperature loss of finished materials and ensure long-term storage;

④ The outer shell of the warehouse is covered with colored steel plates, which enhances the overall aesthetics of the equipment.

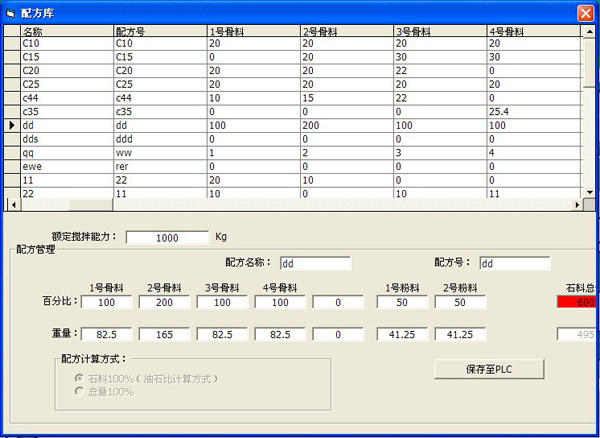

8. Computer control system

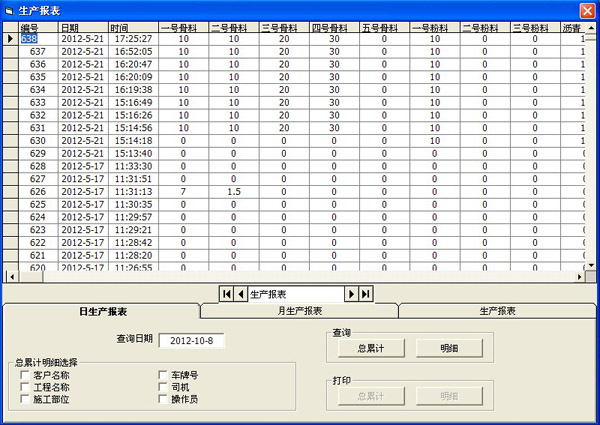

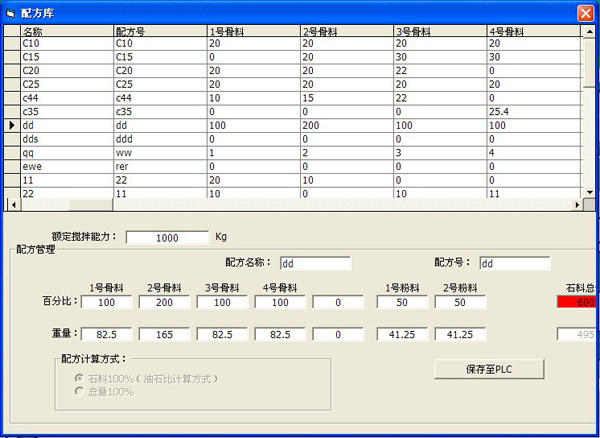

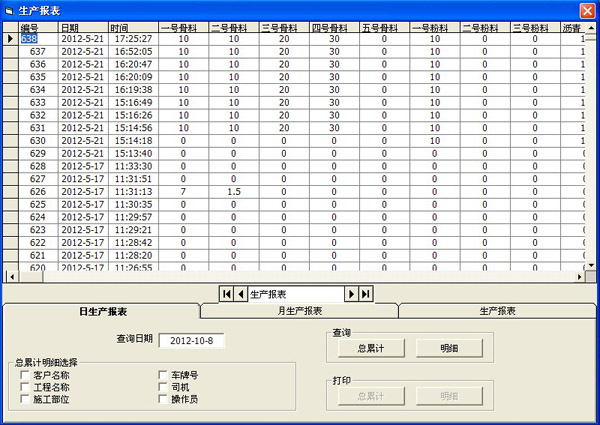

The computer serves as the human-machine dialogue for the entire control system, mainly realizing the start stop control of equipment (issuing control commands), real-time monitoring of equipment operation status (including dynamic display of production ingredients, real-time data and feeding amount of each ingredient, valve stroke display...), data management (user permission management), formula management, production management (production parameters, control parameters, ingredient parameters), production reports (daily production reports, comprehensive production reports), production record management, as well as storing production data, querying and printing various reports. Computer control systems mainly include computers, display devices UPS、 Printers, serial port cards, etc.

控制台

生产报表

生产报表

配方表

配方表