The YHZD/S series mobile concrete mixing plant is a new type of mobile concrete mixing plant designed by our company based on years of experience in producing concrete mixing plants. It is currently an ideal mobile mixing machine in China, with a compact and reasonable design that completes most of the functions of the mixing plant in one traction; Integrated with aggregate collection, electronic weighing, lifting, and mixing, it can be easily moved and installed, making it suitable for various mobile construction sites such as roads, bridges, dams, airports, and construction bases.

1.1 Excellent mixing performance:

The JS series mixer achieves uniform mixing with shorter mixing time. Based on the efficiency of forced mixing, it is suitable for various production processes. With different scrapers, it has high mixing efficiency. The mixing tank is completely covered with interchangeable mixing liners made of special wear-resistant materials, and all blades are shaped according to their specific positions to optimize material flow and reduce wear on the surface of the material and mixing blades. The scraper, mixing blades, and shaft are all fluid designed. Good mixing can be achieved for dry hard, semi dry hard, plastic, and various mix proportions of concrete.

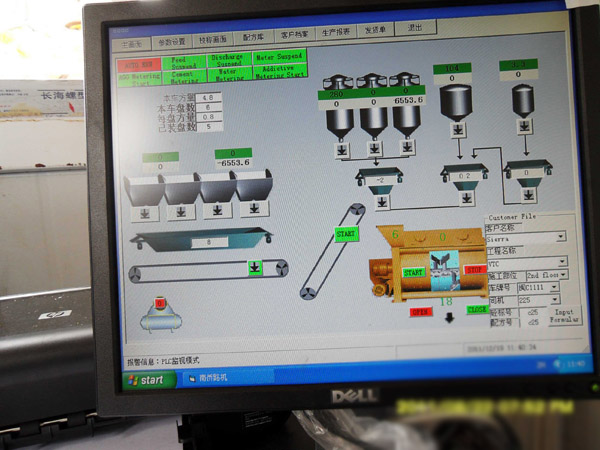

1.2. Simple and clear operation:

The whole machine adopts computer control, which can be operated automatically or manually, with simple operation and easy mastery. Dynamic panel display, which can clearly understand the operation status of each component, and can also store and print report materials.

1.3 Accurate and stable measurement:

Whether it is the measurement of aggregates, powders, water agents, or additives, the measuring and control components are all made of domestic and foreign famous brand components, imported industrial control dedicated computers, and sampling speeds of over 120 times per second, fully ensuring accurate measurement and stable working performance.

1.4. High reliability:

Our weighing system uses imported computerized weighing instruments, with a sampling speed of up to 120 times per second and automatic compensation function. Aggregates, cement, water, and additives are controlled by their respective weighing instruments, ensuring accurate and reliable measurement; Adopting PLC programmable control, the automatic metering, conveying, lifting, mixing, unloading and other functions of the mixing plant can be achieved. It can be operated automatically or manually, and the operation is simple and easy. There are also industrial control microcomputer control management systems available for purchase.

The main electrical components of the control system are all made of well-known domestic and foreign brands, greatly reducing the failure rate of the equipment.

1.5. Convenient and rapid transition:

The overall structure is designed as a trailer, with the batching conveyor, mixing host, and various weighing systems as a whole. Quick disassembly and installation during transition, convenient and fast transportation. The equipment does not require crane assistance during the transfer of construction sites, which can save customers a lot of costs and time.

1.6. Excellent environmental performance:

All powdered materials, from batching, metering, feeding to mixing and discharging, are carried out in a sealed state. Greatly reduces the impact of dust, vibration, and noise on the environment.