The HZS series modular cement concrete mixing plant is suitable for large-scale construction projects such as roads, bridges, dams, airports, and urban commodity concrete centers with high demand for concrete.

Excellent mixing performance:

Configure JS series double horizontal axis forced mixer, with short mixing time and good mixing quality, capable of mixing dry hard, semi hard, plastic and various proportioned concrete.

Simple operational performance:

The whole machine is controlled by a computer, which can be automatically controlled or manually operated. The operation is simple and easy to master. Dynamic panel display, which can clearly understand the operation status of each component, and can also store and print report materials.

Accurate measurement performance:

The measuring and control components for aggregates, powders, and water agents are imported and controlled by microcomputers, with a sampling speed of over 120 times per second, fully ensuring accuracy and stable performance.

Convenient transition installation:

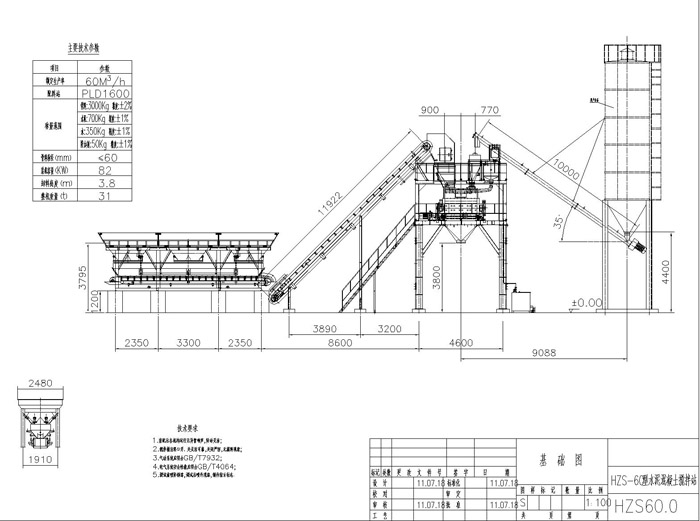

The overall structure is modular. The batching machine, belt conveyor, mixing main building, screw conveyor, and powder tank are all independent structures. The main mixing building consists of several independent modules. Quick disassembly and installation during transition, convenient and fast transportation. And it has multiple layout forms to adapt to the needs of different venues.

Control system:

By using industrial control computers and high-precision weighing systems, data collection and fully automatic production control are achieved through control software based on concrete production processes and quality requirements. Real time production data information is recorded, and various production reports can be queried/printed using data management. The system hardware configuration is scientific, the selection is reasonable, and the principle of global procurement is adhered to. International level brand products are the main selection range. The overall stability of the system is good, with powerful functions and easy operation;

Main functional features of the software:

1. Automatic continuous production function, thereby improving production efficiency.

2. The total number of batches and the number of batches can be automatically converted to reduce workload and the possibility of misoperation

3. The functions of automatic replenishment, automatic deduction, and automatic adjustment of material parameters have improved the accuracy of ingredient preparation.

4. Automatic moisture content conversion function.

HZS series modular concrete mixing plant

Note: 1. The total power does not include the power of the screw machine; 2. The silo and capacity can be designed according to requirements; 3. The above parameters may change, subject to the product.